Welcome to browse Dongguan Feechuang Laser Technology Co., Ltd. website!

Welcome to browse Dongguan Feechuang Laser Technology Co., Ltd. website!

Time:2020-11-19 Views:153

Taking pictures of tourists when traveling, taking pictures of food before eating, and sending a selfie in a good mood... Taking pictures in the circle of friends has become a daily life for most people. At this time, it is particularly important to have a mobile phone with powerful camera function. Many mobile phone manufacturers are also struggling to take pictures.

"Twenty million soft-light dual cameras, illuminate your beauty", "This moment, clearer", "Photographing people are more beautiful"... the advertisements surrounding the camera function are more powerful than each.

There are many doorways to "illuminate your beauty". The production process of the small mobile phone camera assembly is not simple, and the laser welding machine is indispensable.

First understand a term: VCM motor, VCM (Voice Coil Motor), the Chinese name is voice coil motor. Originally used for speakers to produce vibration and sound, it is now used to drive the lens to move to produce an imaging module for auto-focusing.

The main principle is that the coil and the lens barrel are fixed together, and by changing the DC current of the coil in the motor, the stretched position of the spring leaf is controlled to make the lens barrel move back and forth with the lens.

The simple point is that when the mobile phone camera focuses on subjects at different distances, this gadget will help the lens achieve autofocus.

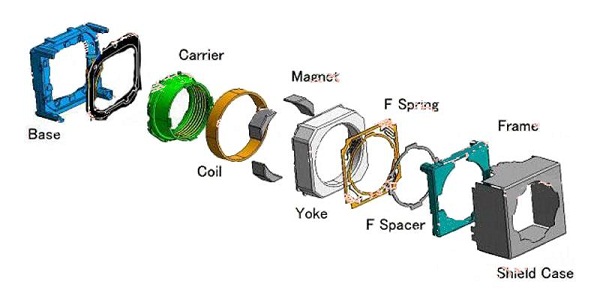

The VCM structure of different vendors is slightly different, roughly divided into the following major components:

Common VCM structure

Shield Case: Shell Frame: Bracket F.Spacer: Front gasket, used to insulate F.Spring: Front spring, used to carry the carrier, balance torque Yoke: used to fix other components, magnetic Magnet: magnet, generate permanent magnetic field Coil: coil, energized to generate driving torque Carrier: carrier, used to carry the lens B.Spacer: rear spacer, used for insulation B.Spring: rear spring, used to carry the carrier, balance torque Base: base, used to fix the components.

There are so many parts in the size of the nail cap. It can be imagined how high the precision of VCM processing is. In such a precise processing process, the advantages of laser welding can be fully utilized.

●High quality of laser welding seam;

●Laser welding speed is fast, production efficiency is high, control is simple, and it is easy to realize automation;

●Because the laser processing is non-contact type, it can avoid the problem of residue and static electricity during processing.

Contact